Máy cắt laser CO2 cấu hình cao là thiết bị cắt laser sử dụng tia laser CO2 công suất cao làm năng lượng để cắt các vật liệu khác nhau với độ chính xác cao và tốc độ cao. Chúng thường có khu vực làm việc lớn hơn so với máy cắt laser tiêu chuẩn, cho phép chúng xử lý các tấm vật liệu lớn hơn. Chúng cũng thường có hệ thống nạp và dỡ hàng tự động giúp đơn giản hóa quy trình cắt và giảm khối lượng công việc của người vận hành.

AccTek Laser có 10 năm kinh nghiệm sản xuất máy cắt laser và cam kết cung cấp các giải pháp laser chuyên nghiệp cho khách hàng toàn cầu. Là nhà sản xuất máy cắt laser CO2 chuyên nghiệp, chúng tôi đã thiết kế các máy cắt laser với công suất và chức năng khác nhau để đáp ứng nhu cầu của các khách hàng khác nhau. AccTek Laser thực hiện quy trình lắp ráp nghiêm ngặt và linh kiện thương hiệu đẳng cấp thế giới để đảm bảo máy cắt laser CO2 chất lượng cao cho khách hàng.

Máy cắt laser CO2 được trang bị một bàn làm việc dạng dải nhôm, có thể cắt và xử lý nhiều loại vật liệu một cách hiệu quả, bao gồm gỗ, nhựa, vải, giấy, da và thậm chí cả kim loại. Bàn làm việc cũng được trang bị các bộ phận bảo vệ an toàn để giúp bảo vệ người dùng khỏi mọi nguy cơ tiềm ẩn.

Bộ điều khiển RDC6445 Ruida là bộ điều khiển máy khắc và cắt laser mạnh mẽ và đa chức năng. Nó không chỉ hỗ trợ điều khiển máy tính qua cáp USB mà còn hỗ trợ điều khiển ngoại tuyến U-disk. Nó cũng có khả năng chống điện áp cao và khả năng chống tĩnh điện tốt.

Ống laze Reci CO2 là một máy phát laze mạnh mẽ có khả năng tạo ra chùm tia laze công suất cao để khắc và cắt các vật liệu khác nhau. Được biết đến với độ bền và độ chính xác, nó cũng tương đối dễ vận hành và bảo trì.

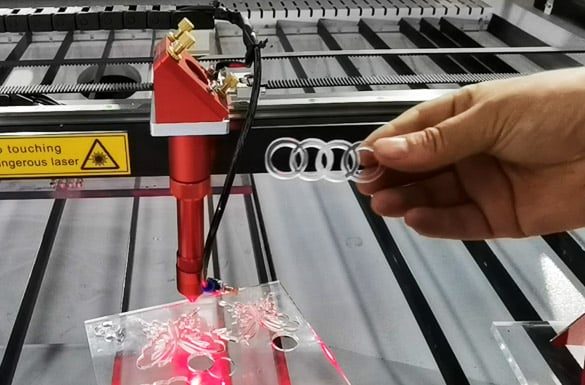

Đầu laser CO2 có độ chính xác cao được chọn và có chức năng định vị chấm đỏ. Đầu cắt luôn bám sát vật liệu và giữ nguyên vị trí của điểm cắt. Một ống dẫn khí cũng được lắp trên đầu laser, luồng khí thổi ra sẽ không chỉ thổi bay không khí mà còn làm mát thấu kính và bề mặt của vật thể.

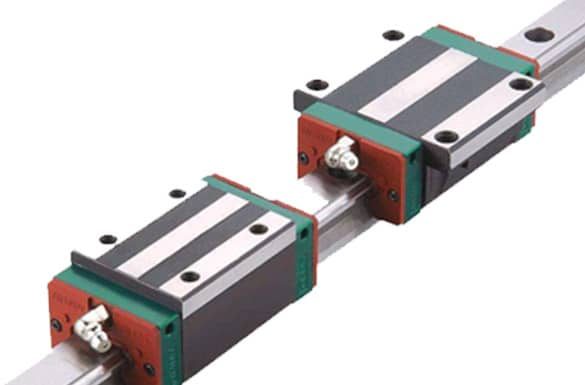

Sử dụng đường ray dẫn hướng tuyến tính HIWIN của Đài Loan, tốc độ chạy nhanh, độ chính xác định vị cao, thời gian dài hơn, độ chính xác khắc và cắt được cải thiện, đảm bảo hiệu quả xử lý chính xác.

Động cơ bước có công suất mạnh và hiệu suất đáng tin cậy được chọn để đảm bảo máy hoạt động bình thường. Động cơ không chỉ có giá rẻ mà hiệu suất còn tốt, không cần chuyển đổi A/D và tín hiệu xung kỹ thuật số có thể được chuyển đổi trực tiếp thành dịch chuyển góc.

| Mẫu | AKJ6040 | AKJ9060 | AKJ1390 | AKJ1610 | AKJ1325 | AKJ1530 |

| Khu vực làm việc | 600*400mm | 900*600mm | 1300*900mm | 1600*1000mm | 1300*2500mm | 1500*3000mm |

| Loại laze | Laser CO2 | |||||

| Bàn làm việc | Bàn dao / Bàn tổ ong | |||||

| Công suất laser | 80W, 90W, 100W, 130W, 150W, 180W, 220W, 300W | |||||

| Nguồn cấp | 220V/50HZ, 110V/60HZ | |||||

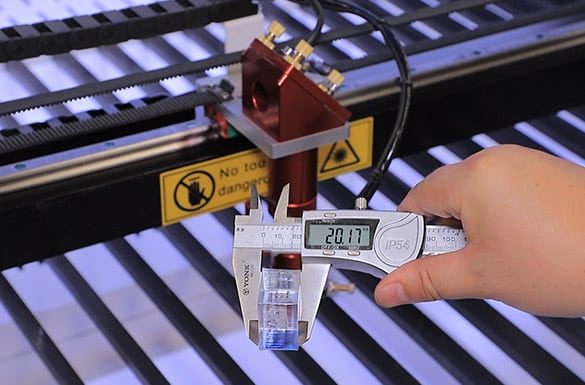

| Chiều rộng dòng tối thiểu | ≤0,15mm | |||||

| Độ chính xác của vị trí | 0,01mm | |||||

| Độ chính xác lặp lại | 0,02mm | |||||

| Định dạng đồ họa | PLT, DXF, BMP, JPG, AI, v.v. | |||||

| Môi trường làm việc | 0-45℃ | |||||

| Độ ẩm hoạt động | 5-95% | |||||

The price of a 1500w laser cleaning machine can vary depending on several factors including the manufacturer, model, features, and other accessories included. Generally, the price range for a 1500w laser cleaning machine is between $6,000 and $18,000. If you need automation or other advanced features, the price may be higher. Note that these prices are estimates only and may change over time.

For accurate pricing information on a specific 1500w laser cleaning machine, it is best to contact the laser cleaning equipment manufacturer directly. AccTek Laser is a professional laser cleaning machine manufacturer, if you want to get accurate price information for a 1500w laser cleaning machine, you can contact us. We can also provide you with details on pricing and any additional costs associated with the machine, such as shipping, installation, or training. Additionally, our engineers will provide you with information on pricing and options, and recommend the best laser cleaning machine for your application and budget.

Maintenance and operating costs for a 1500w laser cleaning machine can vary based on several factors, including specific models, usage patterns, and local market conditions. While I do not have access to real-time pricing information, I can give you some general considerations regarding the costs associated with laser cleaning machines.

It is important to note that actual costs may vary significantly depending on the circumstances. For accurate and up-to-date information on the maintenance and operating costs of a particular 1500W laser cleaning machine, it is best to consult the manufacturer or supplier of the machine you are considering. They can provide you with details on maintenance schedules, expected consumables, and any other specific costs associated with their products.

A 1500w laser cleaning machine is generally capable of effectively cleaning a wide variety of surfaces and materials. The specific applicability and effectiveness of laser cleaning depend on factors such as laser wavelength, pulse duration, and the nature of the surface being cleaned. Here are some examples of surfaces that can be effectively cleaned using laser cleaning:

It is important to note that while 1500w laser cleaning machines are powerful and versatile, the suitability of laser cleaning for a particular surface or material may also depend on factors such as surface sensitivity, composition, and the specific type of laser used. The specific settings and parameters used to clean the material need to be adjusted according to the characteristics of the material and the desired cleaning effect. It is recommended to consult the manufacturer’s guidelines and to test to determine the best parameters for cleaning different surfaces/materials.

Yes, when using a 1500w laser cleaning machine, there are several safety precautions and certifications that need to be followed to ensure the safe operation of the equipment. Laser cleaning machines can be potentially dangerous if used incorrectly. Here are some important security considerations:

Be sure to consult the manufacturer’s documentation, owner’s manual, and relevant safety guidelines for the specific safety precautions and certifications required for your particular 1500w laser cleaner. In addition, local regulations and safety standards may vary, so it is advisable to consult local authorities or a laser safety expert to ensure compliance with all applicable safety requirements.